Tissue Machine

Tissue Machine Specification

- Grade

- Industrial

- Type

- Automatic Tissue Machine

- Material

- Stainless Steel

- Computerized

- Yes

- Control System

- PLC Controlled

- Cutting Size

- 180mm x 200mm

- Voltage

- 220V/380V

- Power

- 5.5 kW

- Weight (kg)

- 2600 kg

- Dimension (L*W*H)

- 7000mm x 2200mm x 2000mm

- Color

- White & Blue

Tissue Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About Tissue Machine

Tissue Machine

We offers a wide range of Tissue Machine. The machine adopts the vacuum to hold the folding paper and with automatic stagger counter. The whole machine is of stable running, high speed, folding trimness and high efficiency. It can be added the embossing unit and edge embossing unit depending on the customers requirement.

Advanced Automation for Streamlined Production

The Automatic Tissue Machine employs cutting-edge PLC control and computerized systems to deliver consistent and precise tissue cutting at industrial capacities. With its substantial production footprint, this machine is engineered for businesses requiring reliability and scale, minimizing downtime and maximizing throughput with every operation.

Durable Stainless Steel Construction

Crafted from high-grade stainless steel, the tissue machine ensures longevity in demanding industrial environments. Its sturdy build resists corrosion and wear, promoting a longer service life while simplifying maintenance processes for operators and technical staff.

Tailored for the Indian Market

As a versatile solution for exporters, importers, and suppliers in India, this machine accommodates varied energy infrastructures with both 220V and 380V compatibility. The design addresses the specific needs of the Indian industrial sector, supporting traders and wholesalers in achieving efficient production cycles.

FAQs of Tissue Machine:

Q: How does the automatic tissue machine operate with its PLC-controlled system?

A: The tissue machine utilizes a programmable logic controller (PLC) for automated processes. This ensures precision in cutting, synchronization, and workflow management, allowing for consistent operation and minimal manual intervention.Q: What materials can be processed with this tissue machine?

A: This tissue machine is engineered primarily for producing tissue papers using compatible raw materials in the industry. The stainless steel build ensures it can handle such materials efficiently without risk of contamination or corrosion.Q: When should businesses consider using this machine for their tissue production needs?

A: Businesses with high-volume tissue production requirements should consider this machine. Its automation and capacity make it ideal for meeting heavy demand, reducing labor costs, and improving manufacturing consistency.Q: Where can this tissue machine be installed and operated?

A: The machine is suitable for installation in industrial manufacturing facilities across India. Its size and weight require a spacious factory floor with appropriate voltage supply (220V or 380V) and structural support.Q: What is the process for switching between voltage options?

A: The machine is designed for flexible voltage operation. Adapting between 220V and 380V may require a certified technician to adjust the settings and ensure wiring compatibility, maintaining safe and optimal performance.Q: How does the computerized system benefit day-to-day operations?

A: The computerized controls provide real-time monitoring and adjustments, enhancing accuracy and reducing errors. Operators can manage settings easily, leading to smoother workflow, reduced downtime, and simplified troubleshooting.Q: What are the primary benefits of using this machine for tissue production?

A: Key benefits include high output, reduced manual labor, enhanced precision, and fewer errors due to PLC and computerized controls. The robust stainless steel design further ensures durability and lower maintenance needs, supporting long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Facial Tissue Machine Category

10 TPD Facial Tissue Machine

Minimum Order Quantity : 1 Unit

Grade : Other, Industrial Grade

Color : Blue & Silver

Computerized : Yes

Voltage : 380V/50Hz, 3 Phase

Control System : Other, PLC Touch Screen

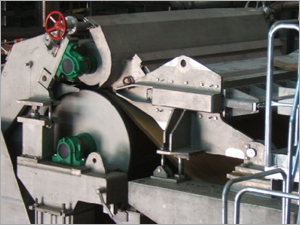

Crescent Former

Minimum Order Quantity : 1 Unit

Grade : Other, Industrial Grade

Color : Blue / Grey

Computerized : Yes

Voltage : 380/415 V

Control System : Other, PLC Controlled

Industrial Tissue Machine

Minimum Order Quantity : 1 Unit

Grade : Automatic

Color : Grey

Computerized : No

Voltage : 220440 Volt (v)

Control System : Human Machine Interface