Crescent Former

Crescent Former Specification

- Grade

- Industrial Grade

- Type

- Automatic Crescent Former

- Material

- Stainless Steel, Mild Steel

- Computerized

- Yes

- Control System

- PLC Controlled

- Cutting Speed

- Up to 300 m/min

- Cutting Size

- Customizable as per requirement

- Cutting Thickness

- Up to 16 mm

- Voltage

- 380/415 V

- Weight (kg)

- 2500 kg (approx.)

- Dimension (L*W*H)

- 4200 mm x 2400 mm x 2200 mm

- Color

- Blue / Grey

Crescent Former Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About Crescent Former

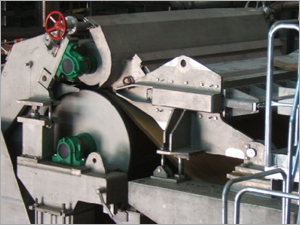

Crescent Former

We offers a wide range of Crescent Former. The machine adopts the vacuum to hold the folding paper and with automatic stagger counter. The whole machine is of stable running, high speed, folding trimness and high efficiency. It can be added the embossing unit and edge embossing unit depending on the customers requirement.

High-Speed Precision Cutting

The Crescent Former delivers high-speed precision cutting, making it suitable for demanding industrial environments. The automatic PLC-controlled system ensures consistent quality and customizable sizes, meeting specific production requirements swiftly and efficiently.

Durable Construction for Longevity

Manufactured using premium stainless steel and mild steel, the Crescent Former offers exceptional durability and reliability. Engineered to withstand heavy-duty operations, its robust frame assures long-term performance with minimal maintenance.

Advanced Automation and Control

Featuring computerized performance and a PLC control system, this machine makes operations straightforward. Users benefit from intuitive controls, precise results, and seamless integration into existing workflows, optimizing processing efficiency.

FAQs of Crescent Former:

Q: How does the Crescent Former benefit my production process?

A: The Crescent Former enhances production efficiency with fast, automated cutting at speeds up to 300 m/min. Customizable sizing and thickness mean it can meet varied operational requirements, reducing manual intervention and boosting output consistency.Q: What materials can the Automatic Crescent Former process?

A: This machine is engineered to handle both stainless steel and mild steel, making it versatile for multiple industrial applications. Its robust construction allows it to cut materials up to 16 mm thick while maintaining precise finishes.Q: When should I consider using the Crescent Former in my workflow?

A: If your operation demands high-volume, precision cutting with customizable sizes and thicknesses, the Crescent Former is an ideal solution. It suits continuous industrial workflows where speed, accuracy, and reliability are paramount.Q: Where can the Crescent Former be installed and used?

A: Thanks to its industrial-grade design and dimensions, the Crescent Former is best installed in factories, workshops, or manufacturing units with sufficient spaceparticularly for exporters, suppliers, traders, and wholesalers across India.Q: What is the process for controlling and operating the machine?

A: The machine is fully automatic and PLC controlled, allowing straightforward operation via computerized interfaces. Users can input specifications for cutting size and thickness, and the system ensures consistent, error-free performance.Q: How do I maintain the Crescent Former for optimal usage?

A: Routine cleaning and timely inspection of mechanical and electrical components will help maintain the machines longevity. Being made of durable materials, it requires minimal maintenance, though regular checks keep operations smooth.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Facial Tissue Machine Category

10 TPD Facial Tissue Machine

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : Other, PLC Touch Screen

Grade : Other, Industrial Grade

Material : Stainless Steel (Frame & Major Parts)

Voltage : 380V/50Hz, 3 Phase

Tissue Machine

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : Other, PLC Controlled

Grade : Other, Industrial

Material : Stainless Steel

Voltage : 220V/380V

Industrial Tissue Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Human Machine Interface

Grade : Automatic

Material : Mild Steel

Voltage : 220440 Volt (v)