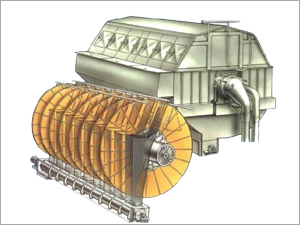

Drum Pulper

Drum Pulper Specification

- Grade

- Industrial

- Type

- Drum Pulper

- Material

- Stainless Steel

- Capacity

- 15100 TPD

- Computerized

- No

- Control System

- PLC Controlled

- Cutting Speed

- Variable, up to 30 RPM

- Cutting Size

- Suitable for large bale or batch pulping

- Cutting Thickness

- Handles up to 20 mm pulp thickness

- Voltage

- 415 V

- Power

- 75 kW

- Weight (kg)

- Approx. 12000 kg

- Dimension (L*W*H)

- 10500 mm x 3050 mm x 3500 mm

- Color

- Blue / Grey

Drum Pulper Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About Drum Pulper

Drum Pulper

We offers a wide range of Drum Pulper, which is of optimum quality and gives high performance. The drum pulper simultaneously disintegrates recovered paper and removes most contaminants from the pulp.

Optimized for Heavy-Duty Industrial Pulping

Our Drum Pulper is tailored for demanding production environments, combining variable cutting speed with significant throughput. Its substantial build and use of stainless steel assure long-term durability, accommodating continuous processing of multiple batches. With cutting capabilities suited for handling large bales and a 20 mm thickness capacity, this machine efficiently enhances productivity for large-scale operations.

Advanced Control and Safety Features

Equipped with a PLC controlled system, the Drum Pulper offers precise monitoring and adjustment options, supporting safe and efficient workflow. The control system allows operators to tailor processing parameters, ensuring optimal pulping results with every batch. Despite its considerable size and power requirements, the pulpers computerized control enhances convenience and reduces operational complexity.

Versatility for the Pulping Industry

Designed for exporters, importers, service providers, suppliers, traders, and wholesalers across India, this Drum Pulper provides broad functionality for various industrial sectors. Its adaptable features, including variable speed and thickness handling, make it suitable for multiple types of pulp materials, supporting consistent quality regardless of the input material.

FAQs of Drum Pulper:

Q: How does the Drum Pulper process large bales or batches of pulp efficiently?

A: The Drum Pulper utilizes a variable cutting speed of up to 30 RPM and can accommodate pulp thicknesses up to 20 mm. Its robust design, combined with PLC control, ensures uniform and rapid pulping of large volumes, making it highly effective for batch or bale processing.Q: What materials and pulp types can this Drum Pulper handle?

A: Constructed from industrial-grade stainless steel and designed to be versatile, this Drum Pulper can process various types of fibrous pulp, including recycled paper, wood chips, and other bulk materials suitable for large-scale manufacturing.Q: When is it suitable to use the Drum Pulper in an industrial setting?

A: The Drum Pulper is particularly effective in facilities requiring high throughput, such as paper mills or recycling plants, where daily production and processing volumes range from 15 to 100 tons.Q: Where can the Drum Pulper be installed and operated?

A: This machine is ideal for installation in industrial environments across India, including large manufacturing warehouses and processing plants with the necessary space and infrastructure for its substantial dimensions and power requirements.Q: What is the control process for operating the Drum Pulper?

A: Operation is managed via a PLC controlled system, allowing operators to adjust cutting speed and monitor performance efficiently. This ensures precise control over pulp quality and process consistency while minimizing manual intervention.Q: How is the Drum Pulper used to maximize production benefits?

A: By handling large batches and thicker pulp, this Drum Pulper increases production rates, reduces manual labor, and delivers a consistent pulping process. Its versatility enhances operational efficiency for exporters, suppliers, and manufacturers alike.Q: What are the main benefits of choosing this Drum Pulper for industrial pulping needs?

A: This Drum Pulper offers heavy-duty performance, reliability, and versatility. Its ability to process large volumes at variable speeds improves productivity, while PLC controls promote safety and operational consistency, making it a preferred choice for large-scale industry professionals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pulping Lines And Paper Machines Category

Hi End Calender

Minimum Order Quantity : 1 Unit

Computerized : Yes

Grade : Other, Industrial

Color : Silver Grey

Material : Mild Steel, Stainless Steel

Voltage : 220 V

Rewinder

Minimum Order Quantity : 1 Unit

Computerized : Yes

Grade : Other, Industrial

Color : Blue / White

Material : Mild Steel

Voltage : 220/380 V

Multi Disk Filter

Minimum Order Quantity : 1 Unit

Computerized : No

Grade : Other, Industrial

Color : Blue / Black / Grey

Material : Plastic, Metal (body and disks)

5 Stage De Inking Cell

Minimum Order Quantity : 1 Unit

Computerized : No

Grade : Other, Industrial

Color : Green / Blue (customizable)

Material : Mild Steel / Stainless Steel

Voltage : 415 V