3 Stage De Inking Cell

3 Stage De Inking Cell Specification

- Grade

- Industrial Grade

- Type

- 3 Stage De Inking Cell

- Material

- Mild Steel / SS304

- Computerized

- No

- Voltage

- 415 V / 380 V

- Dimension (L*W*H)

- (per design) e.g. 4500 mm 1800 mm 2500 mm

- Color

- Blue / Grey

3 Stage De Inking Cell Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About 3 Stage De Inking Cell

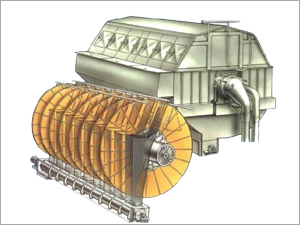

3 Stage De Inking Cell

We offers a wide range of 3 Stage De Inking Cell, which is to remove the printing inks, stickies that might effect the paper making process. In a 3 Stage De Inking Cell process ink is detached from fiber.

High-Efficiency De-Inking Solution

Utilizing a 3-stage process and powerful helical or double helical agitators, this de-inking cell effectively separates ink from recyclable paper with up to 98% efficiency. The multi-stage design ensures thorough treatment, maximizing ink removal and resulting in higher-quality pulp for paper production or further processing.

Robust Industrial Design

Constructed from Mild Steel or SS304, the de-inking cell ensures both durability and resistance to corrosion. The equipment features IP55-protected motors, safeguarding them against dust and water, making it suitable for challenging industrial environments. Its adaptable floor-mounted or skid-based installation fits varying plant layouts.

Versatile Installation and Operation

Designed for convenience, the de-inking cell can be customized in dimensions and installed with ease. It does not require computerized control, allowing straightforward operation and easy maintenance. Suitable for various sectors, it addresses the needs of exporters, importers, suppliers, traders, and wholesalers in India.

FAQs of 3 Stage De Inking Cell:

Q: How does the 3 Stage De-Inking Cell operate to remove ink from pulp?

A: The 3 Stage De-Inking Cell uses a combination of helical or double helical agitators to mix and aerate the pulp, encouraging the ink particles to detach and float to the surface for removal. The three-stage process ensures multiple opportunities for de-inking, enhancing the final product quality.Q: What types of materials and feed stock are compatible with this system?

A: This de-inking cell is suitable for a wide range of paper and pulp feed stocks. Its flexibility allows it to handle various grades of recycled paper, accommodating industry needs while achieving up to 98% de-inking efficiency, depending on the input quality.Q: When is it recommended to use a 3 Stage De-Inking Cell instead of a single stage?

A: A 3 Stage De-Inking Cell is recommended when higher de-inking efficiency is required, or when processing more heavily inked or lower-grade recycled paper. Multiple stages ensure that stubborn ink particles are thoroughly removed, yielding cleaner pulp for further use.Q: Where can this de-inking cell be installed effectively within a facility?

A: The de-inking cell can be installed on the shop floor or on a skid, making it compatible with a variety of industrial facility layouts. Its adaptable design and dimension customization allow for efficient integration into both new and existing production lines.Q: What are the benefits of choosing a system with IP55 motor protection?

A: Motors with IP55 protection are safeguarded against dust and water ingress, ensuring reliable operation even in harsh industrial settings. This increases the systems longevity and reduces maintenance needs, providing additional value and peace of mind to plant operators.Q: How is the equipment maintained and operated without computerized controls?

A: The system operates through manual or basic electrical controls, making it easy to maintain without specialized skills or computerized interfaces. Routine checks on the agitator, motor, and de-inking stages ensure smooth performance and sustained efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pulping Lines And Paper Machines Category

Rewinder

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Grade : Other, Industrial

Computerized : Yes

Color : Blue / White

Voltage : 220/380 V

News Print Machine

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Grade : Other, Industrial Grade

Computerized : Yes

Color : White & Blue

Voltage : 380 V

Multi Disk Filter

Minimum Order Quantity : 1 Unit

Material : Plastic, Metal (body and disks)

Grade : Other, Industrial

Computerized : No

Color : Blue / Black / Grey

5 Stage De Inking Cell

Minimum Order Quantity : 1 Unit

Material : Mild Steel / Stainless Steel

Grade : Other, Industrial

Computerized : No

Color : Green / Blue (customizable)

Voltage : 415 V