5 Stage De Inking Cell

5 Stage De Inking Cell Specification

- Grade

- Industrial

- Type

- De Inking Cell

- Material

- Mild Steel / Stainless Steel

- Capacity

- 500 LPH to 30000 LPH (Litres per hour)

- Computerized

- No

- Voltage

- 415 V

- Dimension (L*W*H)

- Depends on capacity; standard 1800x1000x1200 mm per cell

- Color

- Green / Blue (customizable)

5 Stage De Inking Cell Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About 5 Stage De Inking Cell

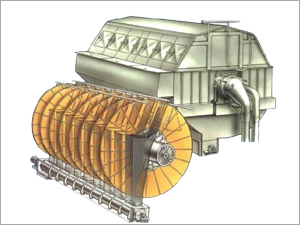

5 Stage De Inking Cell

We offers a wide range of 5 Stage De Inking Cell, which is to remove the printing inks, stickies that might effect the paper making process. In a 3 Stage De Inking Cell process ink is detached from fiber.

Efficient De-Inking for Paper Recycling

The 5 Stage De Inking Cell streamlines pulp cleaning for recycling operations. By systematically removing ink, it enhances pulp quality and promotes sustainable reuse of paper waste. With a customizable design, this cell serves as an integral component for industrial-grade recycling plants, contributing to both environmental preservation and resource efficiency.

Industrial-Grade Construction for Longevity

Manufactured from mild steel or stainless steel, the cell provides corrosion resistance and lasting durability. Whether operating at lower or higher capacities, the sturdy build ensures reliability across extensive industrial use. Color customization in green or blue allows integration into any facilitys aesthetic or branding requirements.

FAQs of 5 Stage De Inking Cell:

Q: How does the 5 Stage De Inking Cell operate in a paper recycling process?

A: The cell works by separating ink particles from paper pulp through a multi-stage flotation and air mixing technique. This results in cleaner pulp that can be reused for high-quality paper production, enhancing efficiency in recycling plants.Q: What are the benefits of using this de inking cell in industrial applications?

A: Using this cell ensures high-quality pulp output, reduces waste, improves recycling efficiency, and lowers operational costs. Its robust construction and customizable features also support long-term, trouble-free performance in demanding environments.Q: When should I consider upgrading or integrating this de inking cell into my production line?

A: You should integrate the 5 Stage De Inking Cell when your facility needs to improve pulp purity, increase processing capacity, or streamline the de-inking process for higher quality output. It is particularly beneficial during modernization or capacity expansion projects.Q: Where can the de inking cell be installed within a recycling facility?

A: The unit is typically installed within the pulp processing section of a recycling or paper manufacturing plant. Its dimensions and modularity allow for flexible installation based on your facilitys available space and capacity requirements.Q: What materials is the de inking cell constructed from, and can its appearance be customized?

A: The cell is available in either mild steel or stainless steel, offering durability and corrosion resistance. It can be painted green or blue, or a custom color as per your facilitys requirements.Q: Is the de inking process computerized in this equipment?

A: No, this model operates without computerized controls, offering straightforward and reliable manual operation suited for industrial environments where simplicity and robustness are prioritized.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pulping Lines And Paper Machines Category

Drum Pulper

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Grade : Other, Industrial

Computerized : No

Color : Blue / Grey

Control System : Other, PLC Controlled

News Print Machine

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Grade : Other, Industrial Grade

Computerized : Yes

Color : White & Blue

Control System : PLC Control

Multi Disk Filter

Minimum Order Quantity : 1 Unit

Material : Plastic, Metal (body and disks)

Grade : Other, Industrial

Computerized : No

Color : Blue / Black / Grey

Control System : Manual / Automated available, Other

Drum-Type Pulper

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Grade : Automatic

Computerized : No

Color : Grey

Control System : Human Machine Interface